Additive technologies in medicine were first officially used in 1999, when employees of the American Wake Forest Institute of Regenerative Medicine implanted an organ made by computer tomography and a 3D printer into a person.

Now 3D-printing in medicine is quite an extensive list of directions and possibilities. Among them are:

The creation of implants;

bone printing;

Modeling human internal organs;

creation of medical instruments for doctors.

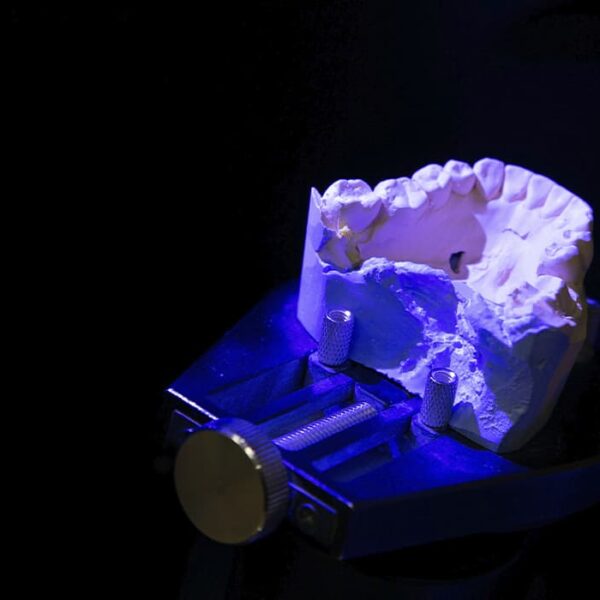

3D printing in medicine makes it possible to accurately model and create dental implants, prostheses, and organ prototypes. 3D printing also helps existing specialists and medical professionals to learn and improve their skills more effectively, to practice and to make accurate plans for surgical operations.

With the advent of new and more advanced printing devices and the expansion of the list of materials, additive technologies in medicine are developing more and more rapidly. 3D printing is most actively used in the United States.

For example, in 2019, a patient from Florida had his first finger bone transplanted with a 3D-printed device. And Michael Winkler, a professor of radiology and cardiology at the University of Kentucky, created a 3D-printed model of the heart that doctors can work with. Such prototypes of organs help surgeons to plan surgeries more accurately and increase the chances of a patient’s quick recovery.

Scientists from all over the world are working on the invention of an optimal material for volume printing of bones. For example, researchers from Northwestern University in the United States in 2016 came up with an elastic and simultaneously durable material for this purpose.

Specialists from the National Nuclear Research University have created a biocompatible material for bone printing that is compatible with the human body. It is based on the composition of animal bones, so that it is not rejected when implanted. The material is quite plastic, but it hardens quickly and then gradually dissolves: the body has time to fuse the damage quickly and without side inflammatory processes.

This significantly speeds up the treatment process, reduces the risk of complications and avoids the need for a second surgery, as is the case with titanium implants, which must be removed after a period of time.

This technology is implemented as follows: biocement is loaded into a 3D printer and the damaged bone is scanned. Based on the information obtained, a three-dimensional model of the fragment to be printed is designed. The implant is made according to the exact design from the bone cement loaded into the printer, and the material hardens right during the manufacturing process, becoming strong and hard.

Using such a SLM-printed device, medical professionals will be able to quickly create individual implants for any person (using their tomography data and other studies as a basis).